If you’ve ever stepped into a lumberyard or browsed wood at a home improvement store, you’ve probably encountered the term “S4S lumber.” But what does it actually mean, and why should you care?

S4S stands for “surfaced four sides,” meaning the lumber has been planed smooth on all four sides, including both faces and both edges. This process turns rough-sawn wood into uniform, ready-to-use boards with consistent dimensions and a smooth finish. If you’re building furniture, installing trim, or working on a DIY project, knowing about S4S lumber can help you save time, money, and hassle.

In this guide, we’ll break down everything you need to know about S4S lumber, from its manufacturing process to its suitability for use (and when it’s not).

Understanding S4S Lumber

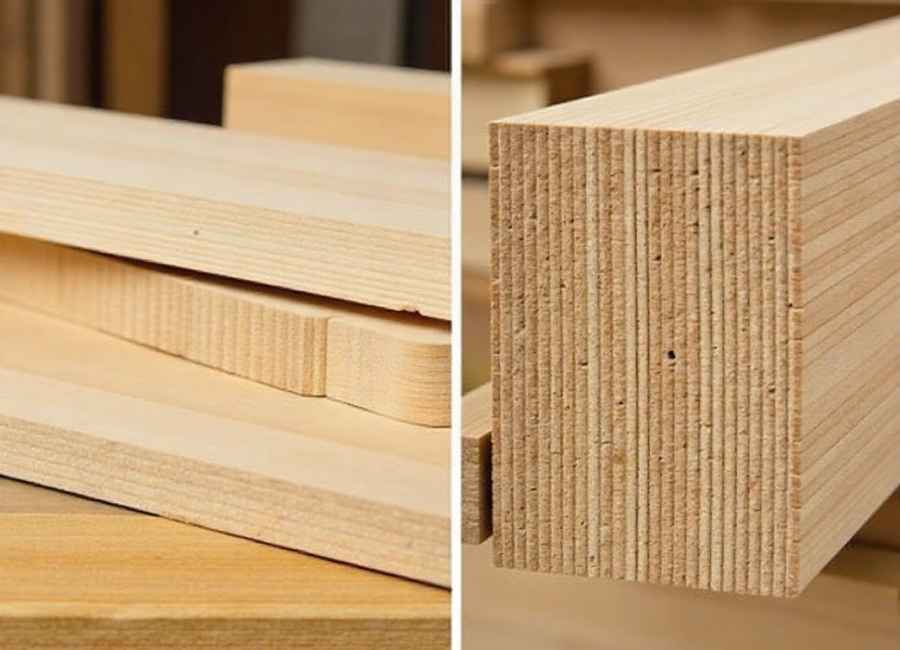

S4S lumber is wood that has been milled on all four sides using industrial planers. The result is a board with flat, smooth surfaces and square edges. This type of lumber is sold with nominal dimensions (like 2×4 or 1×6), but the actual size is smaller due to the planing process.

For example, a nominal 2×4 that has been surfaced will actually measure approximately 1.5 inches by 3.5 inches. (Sizing, n.d.) The size reduction is attributed to the material removed during the milling process. (S4S Lumber: 7 Key Facts For Smart Buyers, n.d.) This standardization makes S4S lumber predictable and easier to work with, especially for projects that require precise measurements.

How S4S Lumber is Made

The process begins with rough-sawn lumber, which is cut directly from logs and features an uneven, textured surface. These boards go through industrial planers that remove thin layers of wood from each side. The planners make sure all four sides are flat, square, and even, resulting in boards with consistent thickness and width.

This surfacing process smooths the wood, bringing out its natural grain patterns and color. The result is lumber that is both useful and attractive from the moment you purchase it.

Benefits of Using S4S Lumber

Time Savings

One significant advantage of S4S lumber is the time it saves. Since the wood is already smooth, you can skip the hard work of milling rough lumber yourself. This is especially helpful if you don’t have a planer or jointer or need to finish your project quickly.

Consistency and Precision

S4S lumber has the exact dimensions from board to board. This consistency is crucial for projects such as cabinets, decks, or framing, where precise measurements are required. You can count on a 1×6 board the same size as every other 1×6 in the pile.

Smooth Finish

The smooth surface of S4S lumber means you spend less time sanding and preparing it for finishing. If you plan to stain or paint your project, this gives you a helpful head start. The wood takes finishes evenly, so your project looks more polished. It is available in various wood species, including pine, oak, cedar, and maple. This variety allows you to select the ideal material for your project, considering its strength, appearance, and budget requirements.

Common Uses for S4S Lumber

Furniture Building

From tables and chairs to bookshelves and bed frames, S4S lumber is ideal for a variety of furniture projects. Its smooth surfaces and even sizes make it easier to join pieces together. You can spend more time on design and assembly instead of milling rough boards. Before being trimmed, baseboards and crown molding are typically made from S4S (Select/No. 4 Surface) lumber. The smooth finish means these decorative elements look polished right out of the box, requiring minimal preparation before installation.

Decking and Fencing

Outdoor projects benefit from FS4S lumber, which is well-suited for outdoor use due to its consistent size. Deck boards stay flat and even, and fence pickets line up nicely. Many pressure-treated boards for these uses are sold as S4S (surfaced on all four sides). When building a planter box, crafting a cutting board, or constructing shelves, S4S lumber provides a user-friendly starting point. Beginners appreciate not having to deal with rough surfaces or uneven boards.

S4S vs. Rough-Sawn Lumber: Which Should You Choose?

S4S lumber is convenient, but rough-sawn lumber can be helpful too. Knowing the differences helps you pick the right one for your project.

Cost Considerations

Rough-sawn lumber usually costs less than S4S because it hasn’t been milled to a smooth finish. (Save Money On Wood – Buy & Mill Rough-Sawn Lumber, n.d.) If you have the right tools and know-how, buying rough lumber can save you money, especially for big projects.

Dimension Flexibility

When you buy rough-sawn lumber, you decide the final size of your boards. This is helpful if you need thicker boards than standard S4S sizes or want to maximize the benefits of high-quality hardwoods.

If your project requires perfectly flat, square boards, starting with rough lumber and milling it yourself can yield better results. However, for most building and woodworking projects, S4S lumber is sufficient.

What to Look for When Buying S4S Lumber

Check for Defects

Although S4S lumber is smooth, it can still exhibit knots, cracks, or warping. Check each board carefully. Inspect the length for twists or bends, and examine the edges for splits or other damage.

Moisture Content

Wood changes size with humidity, so ensure your lumber is dried to the correct moisture level for your project. For indoor furniture, look for wood that has been kiln-dried to a moisture content of about 6-8%. (Kiln Drying Softwood & Hardwood Lumber to Various Dryness Levels, n.d.)

Grade Matters

Lumber is graded based on its appearance and the number of defects it has. (Grading Lumber, n.d.) Higher grades have fewer knots and more even grain, but they cost more. Select a grade that suits your project’s requirements and your budget.

Actual vs. Nominal Dimensions

Please note that the size listed on the label is not the actual size. If you need exact measurements, measure the boards yourself, as even S4S lumber can vary slightly in thickness.

Storing and Handling S4S Lumber

Proper storage protects your investment and ensures your boards stay flat and usable.

Keep It Flat

Store lumber flat on a level surface, with support every few feet. Place spacers between layers to allow air to circulate around the boards. This helps prevent the wood from warping and keeps it straight.

Control the Environment

Store lumber in a place where the temperature and humidity remain steady. Sudden changes can make the wood warp or crack. Allow the wood to adjust to your workspace for a few days before using it.e

S4S lumber can be easily dented or scratched due to its smooth surface. Be cautious when moving boards and avoid dragging them over rough surfaces.

Making the Most of Your S4S Lumber

Knowing about S4S lumber helps you take on projects with confidence. This versatile wood offers a good balance of convenience and quality for most woodworking and building projects. The time you save on milling can be invested in creating better joints, applying finishes, or simply enjoying your project.

When planning your next project, consider whether S4S lumber is the right choice for you. For many jobs, it’s a wise choice that allows you to spend more time building and less time preparing materials. If you’re new to woodworking, using S4S lumber can make things less overwhelming as you learn.

Ready to start? Head to your local lumberyard or home improvement store to explore the S4S options. Now you know what to ask for and what to look for.