Have you ever found the perfect piece of glass for a project, only to realize it’s a bit too big? You might think about cutting it down to size. But if the glass is tempered, you should stop right there. Cutting tempered glass is nothing like cutting regular glass. Instead of a clean cut, you’ll likely end up with a pile of shattered pieces.

So, can you cut tempered glass? The answer is no. In this guide, you’ll learn what tempered glass is, why it acts the way it does, and what to do if you need a specific size. Knowing these details can save you time, money, and a big mess.

What is Tempered Glass?

Tempered glass, often referred to as “safety glass,” is a type of glass that has been treated to be significantly stronger than standard, or “annealed,” glass. The manufacturing process involves heating annealed glass to extremely high temperatures (over 1,100°F or 600°C) and then rapidly cooling it with high-pressure air jets. This process is known as “quenching.”

This rapid cooling causes the outer surfaces of the glass to cool and solidify much faster than the center. As the center continues to cool and shrink, it pulls on the outer surfaces, creating a state of high tension in the core and high compression on the exterior. This internal stress is what gives tempered glass its strength and its unique shattering pattern.

You’ve likely encountered tempered glass in your daily life. It’s used in:

- Car windows (side and rear)

- Shower doors and enclosures

- Glass tabletops and shelves

- Mobile phone screen protectors

- Oven doors and cookware

The main purpose of using tempered glass in these applications is safety. When it breaks, it crumbles into small, pebble-like pieces rather than sharp, dangerous shards, significantly reducing the risk of injury.

Why Cutting Tempered Glass Is Not Possible

The internal stress that makes tempered glass so strong and safe is also the very reason you cannot cut it. The entire pane is in a delicate, high-tension balance. When you try to score and snap tempered glass like you would with annealed glass, you disrupt this balance.

The score line creates a weak point. Scoring tempered glass creates a weak spot that goes through the tough outer layer and reaches the stressed inner layer. This sudden release of energy makes the whole pane shatter right away. Instead of breaking along your score, the glass falls apart into thousands of tiny pieces. It’s not a simple crack or break; the entire piece fails at once. Blades, or techniques that can circumvent this fundamental property. Any attempt to cut, drill, or even sand the edges of a tempered glass sheet will result in it shattering.

How to Tell if Glass is Tempered

Before you attempt to cut any piece of glass, it’s crucial to determine if it’s tempered. Here are a few ways to check:

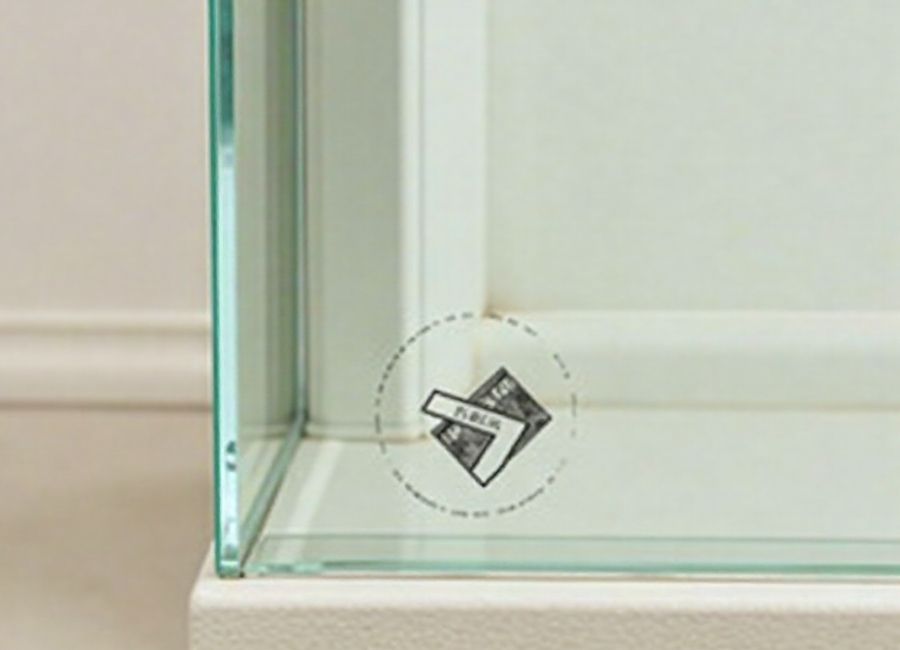

1. Look for a Stamp

Most building codes require tempered glass to be permanently marked with a stamp or “bug” in one of the corners. This label usually indicates the manufacturer’s name and confirms that it meets safety standards (e.g., ANSI Z97.1). If you see this mark, the glass is definitely tempered.

2. Examine the Edges

Tempered glass must be cut to its final size before the tempering process. Because of this, the edges of a tempered pane are always smooth and finished. Annealed glass that has been cut may have rougher, more uneven edges.

3. Check for Imperfections

The intense heating process can sometimes create minor imperfections or surface distortions. Try holding the piece at an angle to a light source. If you notice slight waves, bumps, or roller marks, it’s likely tempered.

4. Use Polarized Sunglasses

This is a neat trick that works well in bright, natural light. Look at the glass while wearing a pair of polarized sunglasses. If the glass is tempered, you should see dark, shadowy lines or spots stretching across its surface. These are stress patterns created during the quenching process and are a clear indicator of tempering.

Your Options if You Need Custom-Sized Tempered Glass

If you have a project that requires the strength and safety of tempered glass but need it in a specific size, you have one primary option: ordering it custom-made.

You will need to provide the exact dimensions—including width, length, thickness, and any required holes or notches—to a glass manufacturer or supplier. They will first cut a piece of annealed glass to your precise specifications and then put it through the tempering process.

While this is more expensive and takes longer than buying an off-the-shelf piece, it is the only way to obtain a properly sized and safe piece of tempered glass tailored to your specific needs.

A Better Way Forward

While the desire to repurpose a handy piece of glass is understandable, the unique physics of tempered glass mean you can’t cut it. The same tension that makes it safe also makes it break if you try to change it. Always check if your glass is tempered before starting a project to avoid a mess and frustration. A custom piece cut to your exact specifications before the tempering process. This ensures you get a product that is both perfectly sized and fully functional, keeping your project safe and secure for years to come.