If you work with CNC machines, you know that every part plays a critical role. While components like the spindle and controller receive considerable attention, the machine bed serves as the foundation of the entire operation. Understanding its function is essential for achieving accurate and high-quality results.

A CNC machine bed serves as the primary structural base for mounting the workpiece. It provides a stable, flat, and rigid surface that supports the material during the machining process. Without a solid bed, it would be impossible to achieve the precision and repeatability that CNC technology is known for.

This guide will explain what a CNC machine bed is, the different types available, and why its design is crucial for optimal performance. Knowing these details will help you choose the right machine and optimize your projects for the best outcome.

The Role of the CNC Machine Bed

The primary function of the CNC machine bed is to provide a solid and immovable foundation for the workpiece. Think of it as the worktable of your CNC router, mill, or lathe. Its stability directly affects the quality of the final product.

Here are the key responsibilities of a CNC machine bed:

- Support: It securely holds the workpiece in place, preventing any movement during machining.

- Stability: It absorbs vibrations generated by the cutting tool and spindle, which is crucial for maintaining accuracy and precision.

- Alignment: It ensures the workpiece is correctly aligned with the machine’s axes (X, Y, and Z), allowing for precise cuts.

A poorly designed or unstable bed can lead to several problems, including dimensional inaccuracies, poor surface finish, and even damage to the tool or workpiece. The bed’s construction is a major factor in the overall performance and reliability of a CNC machine.

Common Materials for CNC Machine Beds

The material used to construct a CNC machine bed is chosen for its strength, rigidity, and ability to dampen vibrations. The goal is to create a base that remains completely stable under the stresses of machining.

Cast Iron

Cast iron is the most popular material for the beds of industrial-grade CNC machines. Its excellent vibration-damping properties make it ideal for high-precision tasks. (Chinnuraj et al., 2020) Cast iron is also very rigid and thermally stable, meaning it won’t expand or contract significantly with temperature changes. (Thermal Expansion Coefficient of a Material, n.d.) This ensures consistent accuracy over long production runs.

- Benefits: Excellent vibration damping, high rigidity, and thermal stability.

- Common Use: Milling machines, lathes, and high-end industrial routers.

Welded Steel

For many CNC routers and plasma cutters, a bed made from welded steel fabrications is a common choice. (CNC Gantry Plasma Cutting Machine, n.d.) Steel offers great strength and rigidity, and it can be engineered to create a very stable structure. While it doesn’t dampen vibrations as effectively as cast iron, a well-designed steel frame can provide more than enough stability for most applications, especially in woodworking and light metal fabrication.

- Benefits: High strength, cost-effective, and versatile design options.

- Common Use: CNC routers, plasma cutters, and laser cutters.

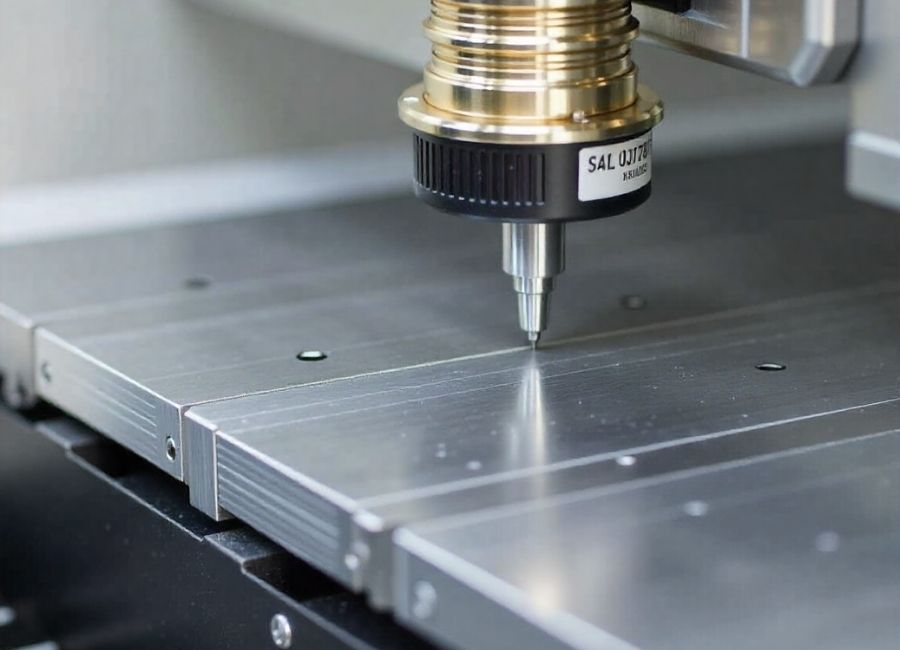

Aluminum Extrusions

Aluminum extrusions, particularly T-slot profiles, are often used for smaller, desktop-sized CNC machines and DIY builds. (Machifit Silver 2020 T-slot Aluminum Extrusions 100-250mm Profiles for CNC Laser Engraving Machine, n.d.) These beds are lightweight, affordable, and easy to assemble. The T-slots make it simple to clamp down workpieces of various shapes and sizes. While not as rigid or vibration-resistant as cast iron or steel, aluminum is sufficient for hobbyist projects and light-duty work.

- Benefits: Lightweight, affordable, and easy to customize with clamps.

- Common Use: Desktop CNC machines, hobbyist routers, and 3D printers.

Types of CNC Machine Bed Designs

The design of the machine bed often depends on the type of CNC machine and its intended application. Two of the most common designs are the flat bed and the T-slot bed.

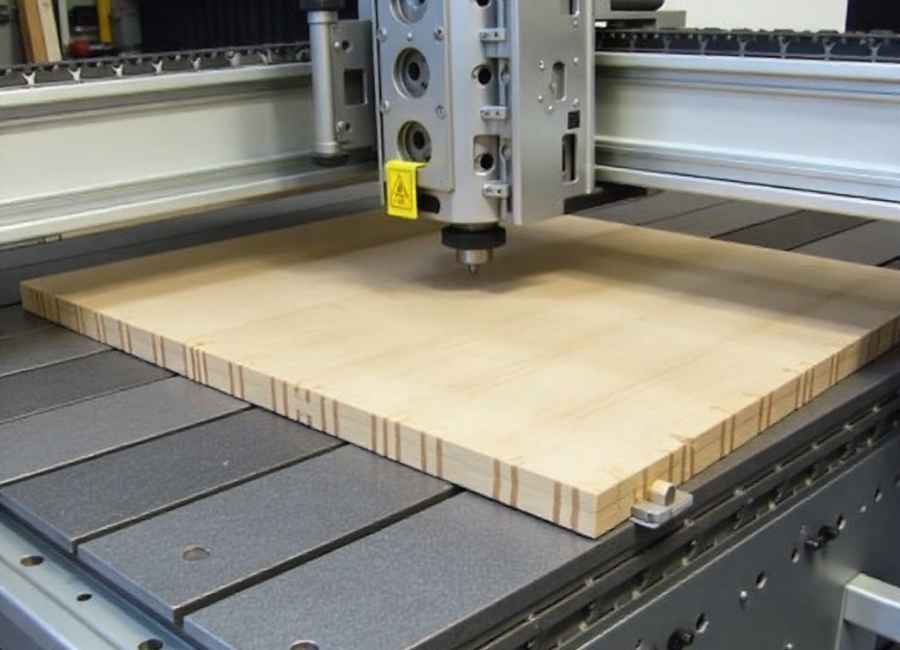

Flat Bed

A flat bed is a simple, solid surface, often found on machines that use a vacuum table or custom fixtures for workholding. In a vacuum table system, a pump creates suction through a series of holes in the bed, holding a sheet of material flat against the surface. This is extremely efficient for machining large, flat materials, such as wood, plastic, or aluminum sheets.

- Advantages: Excellent for holding down large, flat sheets and allows for fast setup.

- Typical Machines: Large-format CNC routers used in cabinet making and sign manufacturing.

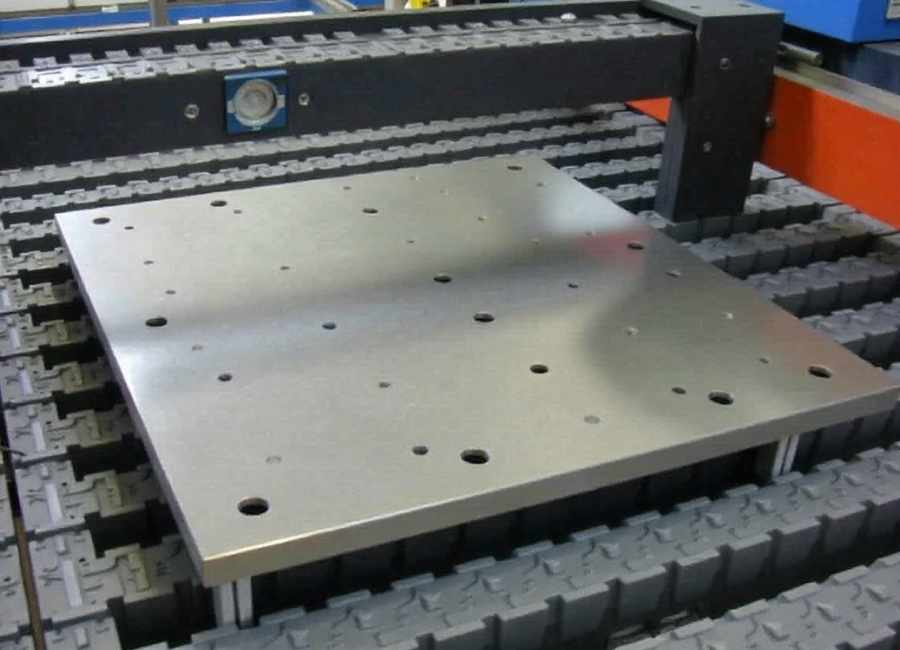

T-Slot Bed

A T-slot bed features a series of T-shaped channels running along its surface. (Mastering the Basics of CNC Machine Bed: Function, Design, and Material Considerations, n.d.) These slots are designed to hold T-nuts, which are used to fasten clamps, vices, and other workholding devices directly to the bed. This design is highly versatile, as it allows you to secure workpieces of almost any shape or size.

- Advantages: Highly flexible, allowing for secure clamping of irregularly shaped parts.

- Typical Machines: CNC milling machines and many general-purpose CNC routers.

Some machines offer a hybrid design, combining a T-slot bed with a vacuum table to offer the benefits of both systems. (Mastering CNC Router Worktables: A Comprehensive Guide, n.d.)

Why a Quality Bed Matters

Investing in a CNC machine with a high-quality bed is crucial for any serious manufacturing or fabrication work. A rigid and stable bed is not just a feature—it is a requirement for achieving professional results.

- Improved Accuracy: A solid bed minimizes vibrations and deflections, ensuring the cutting tool follows its programmed path precisely.

- Better Surface Finish: By reducing chatter (high-frequency vibrations), a stable bed helps produce a smoother surface on the finished part.

- Longer Tool Life: Vibrations can cause premature wear on cutting tools, reducing their lifespan. A stable setup helps extend tool life, saving you money.

- Greater Reliability: A well-built machine with a robust foundation will perform consistently for years, providing a better return on your investment.

When evaluating a CNC machine, pay close attention to the construction of the bed. It is a key indicator of the machine’s overall quality and capability.

Your Foundation for Success

The CNC machine bed is the unsung hero of precision machining. It provides the stable foundation necessary for every cut, ensuring accuracy, quality, and reliability. Whether it’s made from cast iron, steel, or aluminum, its design is fundamental to the machine’s performance.

By understanding the importance of the bed and the different types available, you can make a more informed decision when purchasing a CNC machine. Select a machine with a bed that meets your application’s specific needs, and you will set yourself up for successful projects every time.